Georgetown Researchers Design Effective, Reusable Mask to Fight Airborne Threats

A team of Georgetown researchers are one of Phase 2 Finalists in the running for a $400,000 prize for designing an innovative, lightweight and reusable mask, as highlighted in Science magazine and Scientific American .

Department of Physics professor Kai Liu and Ph.D. students James Malloy (G’22) and Christopher Jensen (G’25) are up against 9 other teams, including scrappy start-ups and industry heavyweights like Amazon and Levi Strauss & Co.

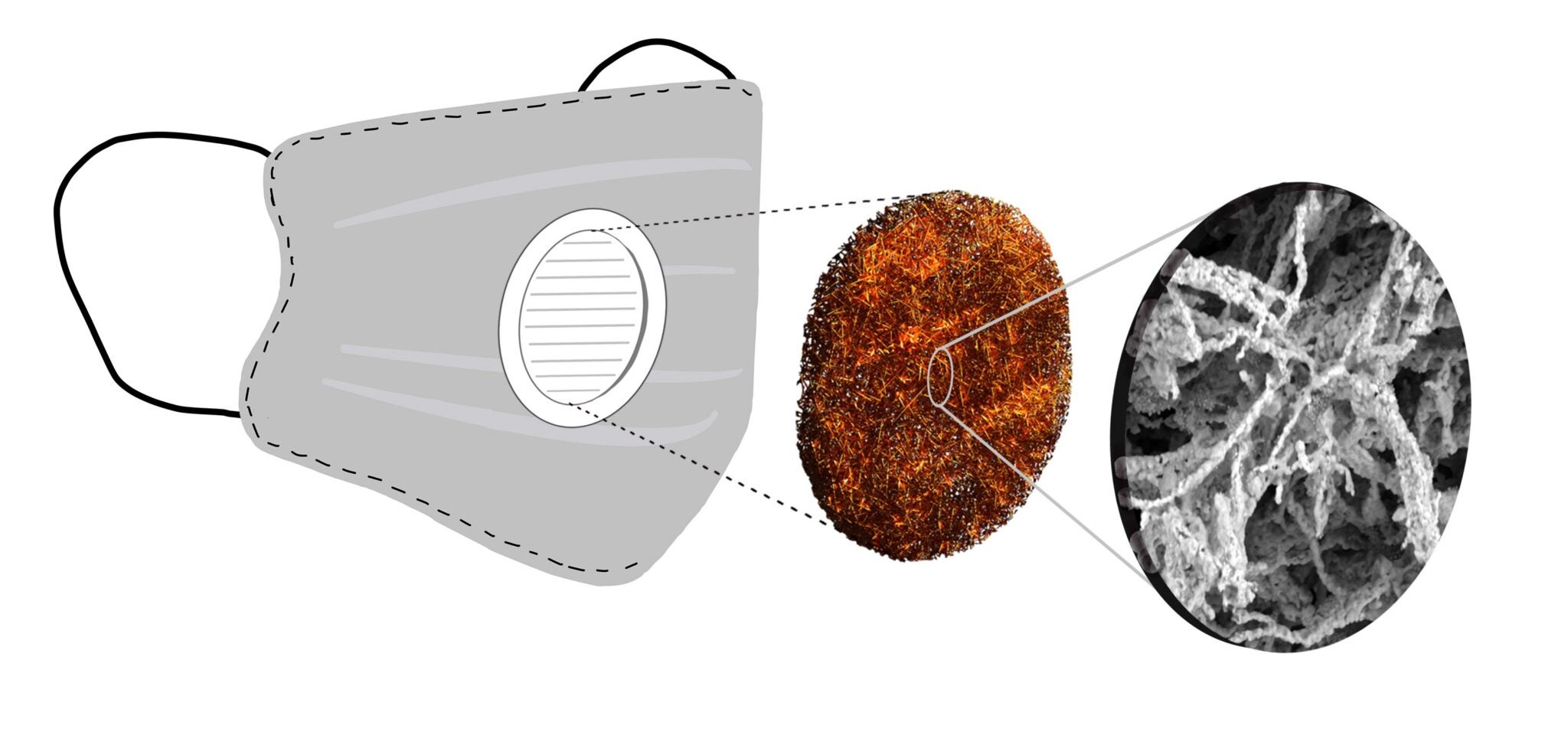

“Our design is a new type of air filtration material based on lightweight nanoporous metal foams that are efficient, breathable, robust, adaptable, cost-effective and can also be cleaned, reused and recycled,” says Liu.

Organized by the Biomedical Advanced Research and Development Authority (BARDA) and the National Institute for Occupational Safety and Health (NIOSH), the Mask Innovation Challenge is poised to help the United States better respond to future airborne threats. The Georgetown team’s design is one of the most novel concepts for next-generation face coverings to protect against respiratory disease pathogens and was selected from among over 1,400 designs originally submitted.

Making a New Type of Mask

Liu’s group transformed copper nanowires into metal foams, which are more durable and have the potential to effectively filter out ultrasmall particulates and microbes. These copper foams have wide ranging applications, including reusable face masks and air filtration systems.

Last year, BARDA’s Division of Research, Innovation, and Ventures partnered with NIOSH to launch the “Mask Innovation Challenge: Building Tomorrow’s Mask,” which aims to support the development of innovative masks that can protect individuals from respiratory pathogens.

The challenge’s overall goals are to “improve the comfort, utility and protective capabilities of products that are worn during day-to-day activities by the general public when physical distancing is not possible.”

While competition participants have an eye on future coronavirus surges, the masks have utility outside of the prevention of COVID-19 as they have been shown to reduce the transmission of other respiratory infections such as the flu. They also provide protection against air pollution, especially for immunocompromised groups.

Currently, the gold standard N95 face masks are difficult to decontaminate and reuse. Their polymer fibers rely on electrostatics, which discharge over time, significantly decreasing the filtration efficiency. The sheer volume of the waste face masks generated during COVID-19 also poses significant environmental challenges, due to the long time it takes for polymer-based materials to decompose.

The copper foams created by Liu and his team of researchers are “light as a feather” and actively filter particulate matter. Feasibility studies have shown that the foams exhibit excellent filtration efficiency for most of the submicron-sized particulates, especially relevant for combating COVID-19 and air pollution.

“The foams can be readily integrated with other mask designs, either as the filtration media themselves, or as inserts or cartridges,” says Malloy. “Our design can also accommodate additional air cleaning mechanisms.”

In the second phase of the challenge earlier this year, the team submitted prototypes that were judged on filtration, fit, comfort and ease of manufacturing

This competition is designed to support the development of mask designs that meet defined performance standards while also overcoming barriers to use. Overall, there is a need to develop better designs, materials, and technologies that are more acceptable to wearers and that ensure quantified measures of performance.

Last year Liu and the Georgetown team were selected as a Phase 1 winner of the competition.